In the ever-evolving world of robotics, Boston Dynamics has consistently remained at the forefront of innovation. Their latest unveiling, the new Atlas humanoid robot, represents a monumental leap not just for the company, but for industrial automation at large. Designed to perform dynamic, complex, and labor-intensive tasks across varied industrial environments, Atlas isn’t just a demonstration of technical prowess—it’s a vision statement for the future of work. In this article, I’ll take an in-depth look at what sets the new Atlas apart, its practical implications across sectors, and how you or your organization can harness the power of this groundbreaking technology.

Table of Contents

- What is Atlas?

- The Evolution of Atlas: From Research to Reality

- Importance of Atlas in Industrial Automation

- Atlas Capabilities in Detail

- How Atlas Works: The Technology Behind the Robot

- Impact on Businesses and Industries

- Workforce and Human Collaboration: Myths and Realities

- Challenges and Ethical Considerations

- Getting Started with Atlas

- The Future of Robotics in Industry

- Summary

- FAQs

- Sources

What is Atlas?

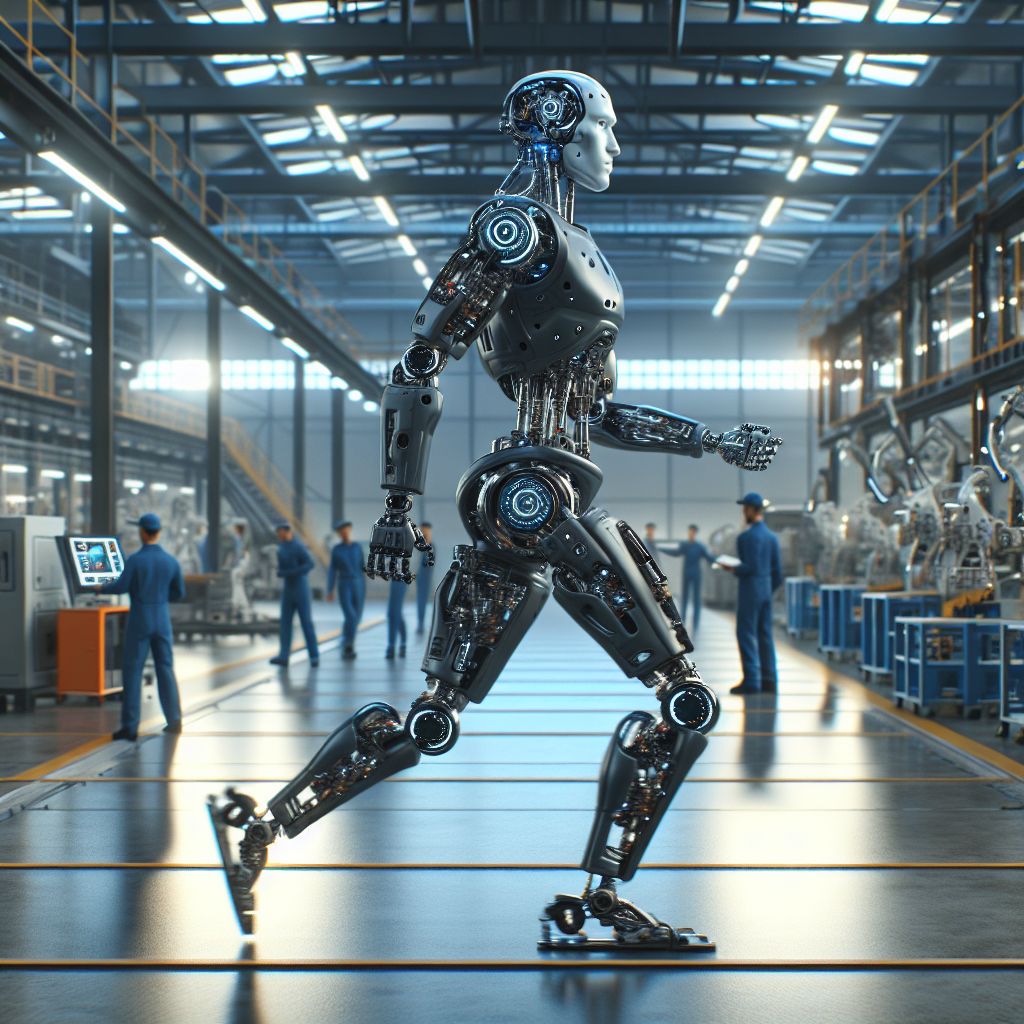

Atlas represents Boston Dynamics’ most advanced humanoid robot to date. Standing at over 5 feet tall and weighing in around 190 pounds, Atlas is designed with human-like proportions and movements, pushing the boundaries of what robots can do in real-world environments. Thanks to articulate limbs, dynamic balance, and perceptive sensors, Atlas can navigate spaces and handle objects as deftly as many humans might.

The new generation of Atlas brings a blend of strength, agility, and adaptability unseen in previous industrial robots. Tasks considered dangerous, repetitive, or ergonomically straining are now within its remit. Atlas is not only capable of walking, running, and jumping but also executing sophisticated maneuvers such as complex object manipulation, spatial reasoning in cluttered settings, and—famously—backflips. For a visual glimpse, you can check out the official video and technical overview.

The Evolution of Atlas: From Research to Reality

Atlas has a storied history rooted in cutting-edge robotics research. First introduced as a research platform in the early 2010s, its design and abilities have made dramatic advances. Early prototypes focused primarily on balance and bipedal locomotion, being tested on rough terrains and obstacle courses. Each iteration brought more natural movement, improved perception, and increased robustness.

Today’s Atlas benefits from years of research across fields such as biomechanics, materials science, machine learning, and real-time control systems. The journey from an experimental prototype, famous for its viral YouTube videos, to a commercial-ready product highlights Boston Dynamics’ commitment to transitioning robotics technology out of the lab and onto the factory floor.

Importance of Atlas in Industrial Automation

Atlas’s arrival signals a shift in how society thinks about automation and the workplace. Whereas industrial robots have excelled at specialized, repetitive tasks—like welding car bodies or assembling electronics—they typically operate inside enclosures with little ability to adapt to unexpected changes in the environment. Human labor, in contrast, is flexible and able to solve unstructured problems quickly.

The new Atlas is engineered to bridge this gap. Its versatile design and AI-driven control systems allow it to handle jobs where adaptability and quick decision-making are essential, such as moving around dynamic warehouses, handling varied product types, or configuring makeshift assembly lines in response to urgent market needs. With industries increasingly focused on flexibility, speed, and safety, Atlas gives businesses a tool that combines the best of human versatility and robotic stamina.

For more on the evolution of automation, you can browse this in-depth automation resource.

Atlas Capabilities in Detail

What specifically can Atlas do? Here’s a closer examination of its capabilities:

- Mobility: Atlas can clamber over obstacles, balance on unsteady surfaces, climb stairs, and even walk backward or sideways. Its bipedal locomotion is informed by years of biomechanical research, allowing it to recover from slips or pushes.

- Object Manipulation: With articulated hands and wrists, Atlas can pick up, carry, place, and assemble items with precision. From moving heavy boxes to using tools, its dexterity is a major step beyond traditional palletizing robots.

- Perception: High-resolution cameras and depth sensors help Atlas build a 3D model of its environment in real time. This enables collision avoidance and careful planning of movement in spaces shared with people and other machines.

- Learning and Customization: Through AI and machine learning, Atlas can be programmed for specific workflows and even learn new skills over time. Its software architecture allows for simulation-based training and deployment across multiple facility types.

- Resilience and Safety: Robust actuators, shock-absorbing design, and sophisticated software allow Atlas to withstand bumps, jostles, and minor falls—crucial in busy workplaces. Multiple redundant safety systems let it detect and avoid people or obstacles instantaneously.

These features mark a significant break from single-purpose robots, allowing Atlas to operate in environments that were previously off-limits to automation.

How Atlas Works: The Technology Behind the Robot

Atlas’s impressive proliferation of movements and skills is powered by a fusion of advanced technology:

- Actuators and Materials: State-of-the-art electric actuators, lightweight alloys, and carefully engineered joints provide exceptional power-to-weight ratios. This allows for fast, fluid motion while keeping the robot stable.

- Robust AI and Machine Learning: Atlas employs neural networks trained on billions of data points—both simulated and real-world. Its AI allows for dynamic adaptation when facing new objects or environments.

- Sensors: Vision (including stereo cameras and LiDAR), tactile sensors, and inertial measurement units continuously inform Atlas’s software about the world around it.

- Real-Time Control Systems: Atlas combines high-speed processors with advanced motion-planning algorithms, meaning it can recalculate a new path or response in milliseconds when its environment changes.

If you’re curious about the inner technical workings, a vast body of research is available on arXiv and similar scientific resources.

Impact on Businesses and Industries

Atlas’s impact stretches across a variety of industries. Here are some prominent examples:

- Manufacturing: The ability to retool production lines rapidly and handle last-minute changes is increasingly valuable. Atlas frees up skilled staff for creative or supervisory roles by taking on the most repetitive or physically demanding tasks.

- Warehousing and Logistics: As e-commerce grows, warehouses must process more orders at higher speeds. Atlas can autonomously pick, sort, and transport goods of differing shapes—hopping over obstacles and navigating dynamic environments with ease.

- Construction: The construction industry is notorious for dangerous, labor-intensive jobs. Atlas’s mobility enables it to carry materials up stairs, assist in demolition and even support assembly tasks under hazardous conditions.

- Healthcare and Emergency Response: In environments that are unsafe for human responders—such as disaster zones or hospitals during pandemics—Atlas can deliver goods, handle medical supplies, or even perform certain repetitive medical tasks.

By combining agility with intelligence, Atlas exponentially increases what is possible in automation. For a deeper dive into business implications, see this discussion on TechCrunch.

Workforce and Human Collaboration: Myths and Realities

Much has been said about robots replacing human jobs, but Atlas is designed for collaboration. Businesses are deploying robots not to replace workers wholesale but to take over tasks that are dangerous, physically exhausting, or highly repetitive. This allows skilled staff to focus on supervision, problem-solving, and creative work.

Atlas can safely work side by side with people, thanks to its advanced sensors and safety protocols. In fact, the rise of collaborative robotics (or “cobots”) is expected to improve job quality by reducing workplace injuries and opening up new, more engaging roles focused on programming, maintenance, or process design. Boston Dynamics offers training on human-robot collaboration, ensuring a smooth transition for any workforce.

Challenges and Ethical Considerations

No technology as transformative as Atlas comes without challenges:

- Cost and Accessibility: While prices will fall with wider adoption, initial investment is significant and may be out of reach for smaller companies in the short term.

- Workforce Transition: Employees whose work is automated will need retraining options—requiring businesses and educational institutions to work together proactively.

- Privacy and Data Security: Atlas’s use of cameras and data collection for navigation prompts concerns about privacy and proper data usage—issues that will need clear regulatory guidance.

- Societal Perception: Media often dramatizes robot deployment as a risk to jobs and safety, though actual deployment paints a more nuanced, collaborative picture.

Companies should proactively communicate with employees and the public about deployment, ensuring an ethical, inclusive implementation that puts human wellbeing first.

Getting Started with Atlas

If you’re considering integrating Atlas into your operations, here’s a practical pathway to adoption:

- Assess Your Needs: Catalog tasks that are repetitive, dangerous, or suitable for automation. Consider areas of highest ROI.

- Consult Experts: Engage Boston Dynamics’ deployment specialists or third-party robotics consultants to evaluate fit and develop integration plans.

- Site Readiness: Prepare your facilities for safe human-robot collaboration, including workflow redesign and safety mapping.

- Training: Invest in training for leadership, supervisors, and floor staff—both on technical operation and on human-robot teamwork.

- Iterative Deployment: Start small with pilot projects and scale up as your organization builds expertise.

- Monitor and Adapt: Use performance data to refine tasks, improve safety, and adapt programming as business needs change.

The Future of Robotics in Industry

Atlas is only the beginning. As AI models grow more powerful and hardware becomes more affordable, humanoid and animal-inspired robots will increasingly populate spaces alongside humans. Expect even greater adaptability, learning-from-observation skills, and cloud-based robot management platforms to further accelerate deployments.

For businesses, adopting Atlas now offers a competitive edge, positioning them as leaders in efficiency, safety, and forward-thinking strategy. Looking ahead, the real winners will be those organizations most prepared to equip their workforce, adapt policies, and ensure a responsible, people-centered approach to the new era of intelligent machines.

Summary

Boston Dynamics’ unveiling of the new Atlas marks a pivotal moment in the history of industrial automation. With its unprecedented agility, intelligence, and operational flexibility, Atlas promises to change the way we think about work, safety, and collaboration between humans and machines. From manufacturing and logistics to construction and healthcare, the range of possible applications grows with each passing year. By taking a strategic, people-first approach to integration, businesses can harness Atlas’s full potential and lead the way in tomorrow’s technology-driven world.

FAQs

- What industries can benefit from Atlas? Atlas finds applications in manufacturing, logistics, warehousing, construction, emergency response, and more—anywhere adaptable automation is needed.

- How much does Atlas cost? Pricing depends on system configuration, facility requirements, and integration needs. Organizations should request a customized quote from Boston Dynamics.

- Is Atlas safe to work with humans? Yes, Atlas is built with multiple safety systems, sensors, and AI protocols to ensure safe operation around people—it can sense, pause, or reroute in real time.

- Can Atlas learn new tasks? Atlas’s machine learning-based architecture allows it to be retrained for new workflows—greatly increasing its versatility across job functions.

- Will Atlas replace human jobs? Atlas is primarily aimed at automating dangerous, repetitive, or physically taxing work, freeing people for complex, creative, or supervisory tasks. Successful deployment is likely to create new roles, requiring a shift—not elimination—of human work.