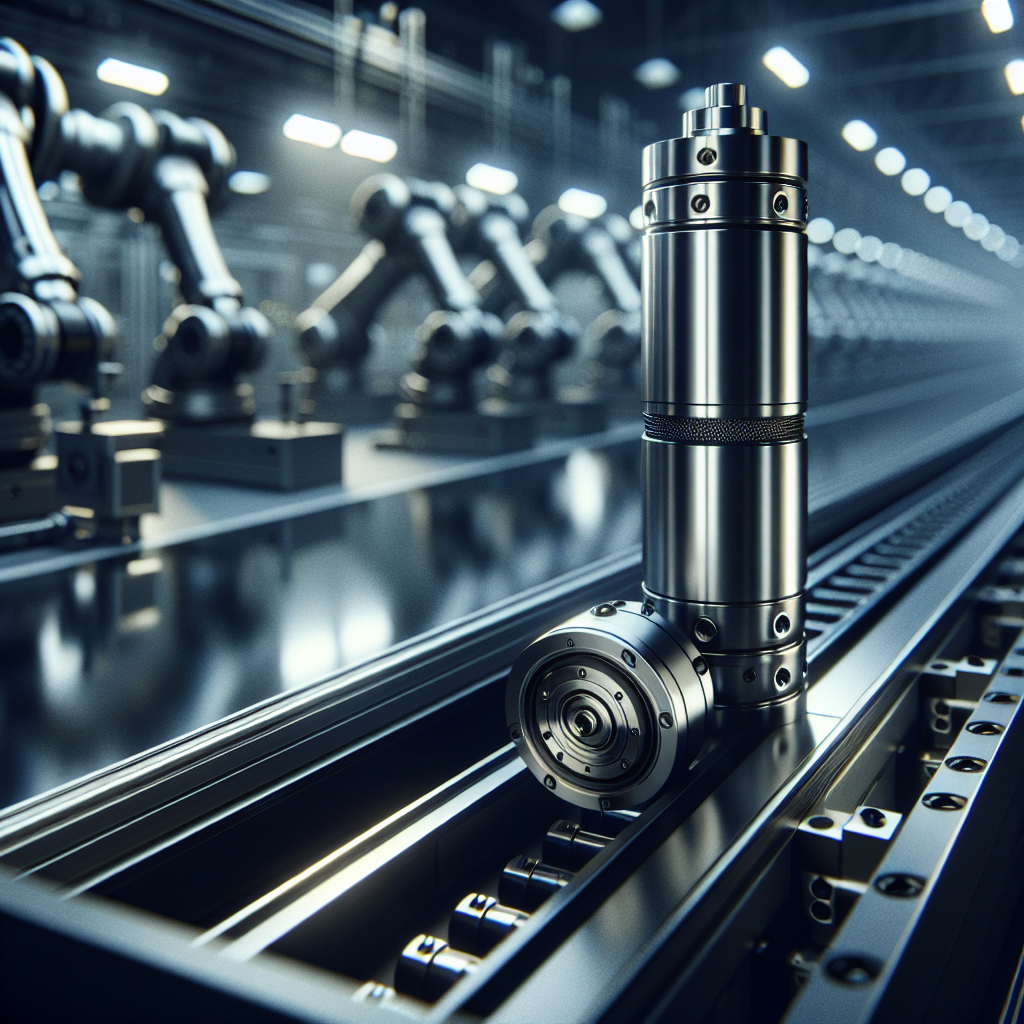

In the world of industrial automation, where machines hum and production lines race against deadlines, precision and reliability are not just desirable—they’re essential. At the heart of this symphony of motion lie components whose roles, though often unsung, are vital for ensuring seamless operation. One such specialized marvel is the MSQB-30A Rotary Pneumatic Cylinder. Distinguished by its adjustable rotation range of 0-190°, robust aluminum alloy body, and exceptional waterproof design, the MSQB-30A is engineered to withstand and excel in demanding industrial environments. This article explores the features, benefits, and best practices for integrating this cylinder into your automation framework, ultimately showing how its innovation can elevate efficiency and streamline operations.

Table of Contents

- Features of the MSQB-30A Rotary Pneumatic Cylinder

- Importance of Pneumatic Cylinders in Automation

- Applications of the MSQB-30A

- Installation and Maintenance Tips

- Best Practices for Maximizing Efficiency

- Troubleshooting Common Issues

- Emerging Trends in Rotary Pneumatic Technology

- Summary

- FAQs

- Sources

Features of the MSQB-30A Rotary Pneumatic Cylinder

Precision and adaptability define the MSQB-30A Rotary Pneumatic Cylinder. Let’s take a comprehensive look at what sets this device apart in today’s fast-paced automation sector:

- Adjustable Rotation Angle (0-190°): Unlike many cylinders with fixed rotational capabilities, the MSQB-30A offers a customizable sweep, allowing system designers to tailor movement to exact application needs. Automated pick-and-place equipment, for instance, benefits tremendously from this flexibility, reducing the need for multiple actuators.

- Lightweight Yet Durable Construction: Built from high-grade aluminum alloy, the MSQB-30A is both strong and relatively light, easing installation and reducing the load on supporting structures. Unlike steel, aluminum resists corrosion, making it more suitable for operations in humid, reactive, or washdown environments.

- Exceptional Waterproofing: One of the standout features, the waterproof construction allows the cylinder to operate safely where moisture, splashes, or even occasional washdowns are present, thereby extending its lifespan and reducing maintenance downtime.

- Integrated Magnetic Ring: This feature dramatically enhances real-time position feedback when paired with compatible sensors. The result? Smoother operations, increased accuracy, and the ability to closely monitor cycle completion in automation platforms.

- Easy Integration: Standardized fittings and mounting options ensure the MSQB-30A can be added to existing lines with minimal modification—a practical advantage for facilities evolving toward greater automation.

For further reading on core pneumatic cylinder technologies, the database at Automation.com offers detailed explanations and technical articles.

Importance of Pneumatic Cylinders in Automation

Pneumatic cylinders—since their widespread adoption in the mid-20th century—have become the muscle behind a broad range of automated tasks. Their universal appeal lies in their simplicity, reliability, and ability to deliver repeatable linear or rotary motions using compressed air. Let’s examine why they’re so indispensable in today’s manufacturing and logistics sectors:

- Safety and Clean Operation: Unlike hydraulic systems that may risk fluid leaks and contamination, pneumatic setups use air and are less likely to cause environmental damage, making them ideal for food, pharmaceutical, and electronics sectors.

- Cost-Effectiveness: Compared to electric actuators, pneumatic cylinders have a lower initial cost and require fewer electrical safety measures. Maintenance costs are also generally lower, as components are simpler and more robust.

- Rapid Response: Air compresses and decompresses almost instantly, permitting rapid actuation. This makes pneumatic cylinders perfect for high-speed automated processes.

- Energy Efficiency (with Proper Management): While older systems might be less efficient, modern pneumatic circuits paired with automation controls can optimize air usage, dramatically reducing energy consumption and operational costs.

- Scalability: It’s easy to expand or reconfigure pneumatic systems as production needs evolve—valuable for industries with varying product lines or seasonal demand shifts.

To learn more about cost-saving strategies through pneumatics, TechCrunch regularly publishes analysis pieces on industrial efficiency.

Applications of the MSQB-30A

The versatility of the MSQB-30A opens the door for its utilization across a wide spectrum of industries. Here are just some specific scenarios where this rotary pneumatic cylinder excels:

- Automated Assembly Lines: The precise control of rotation and stop points is invaluable for assembling complex products, where subcomponents must be carefully oriented and positioned for joining or fastening.

- Pick-and-Place Robotics: In packaging plants, MSQB-30A cylinders power rotary grippers that snatch products and rotate them onto conveyor belts, trays, or packing boxes, ensuring relentless throughput.

- Automotive Manufacturing: From robot arms that insert bolts at exact angles to jigs that reposition panels for welding, these cylinders work behind the scenes to make car production faster and safer.

- Material Handling: Automated sorters and diverters in warehouses rely on rotary actuators to quickly direct packages and materials, minimizing bottlenecks and manual sorting.

- Laboratory Automation: The MSQB-30A is also finding a home in advanced research labs where precise rotary movements are required to operate analyzers or manipulate samples.

- Food and Beverage Processing: Thanks to its waterproofing, the cylinder is ideal for environments where regular cleaning or exposure to water is a part of the process, like beverage bottling or food sorting.

- Entertainment and Special Effects: In amusement rides, theatrical props, or theme park animatronics, rotary pneumatic cylinders deliver consistent, repeatable movements for dramatic flair.

For more real-world stories in cutting-edge automation, Wired.com covers the intersection of technology and industry innovation.

Installation and Maintenance Tips

The MSQB-30A is designed for hassle-free implementation but, like all automation components, benefits greatly from careful handling and routine care. Proper installation and maintenance extend its life and reliability. Here’s a detailed guide to best practices:

- Pre-Installation Assessment: Before installing, review your system’s air supply pressure and quality. The presence of excess moisture or contaminants in compressed air can significantly reduce cylinder life. Use dryers and filters as needed.

- Secure Mounting: Ensure the mounting surface is both robust and level. Use the manufacturer-recommended bolts and tightening torques. This ensures proper alignment, minimizes vibration, and prevents premature wear or misalignment.

- Proper Fittings: Select compatible pneumatic fittings and ensure connections are leak-free. Teflon tape or appropriate sealing compounds can ensure a solid, airtight fit without over-tightening, which can damage aluminum threads.

- Lubrication: While many modern pneumatic cylinders are shipped pre-lubricated and labeled as “lifetime lubricated,” check your operating manual. Use only recommended oils/greases and avoid over-lubricating, as excess lubricant can attract dust and debris.

- Sensor Calibration: If using the integrated magnetic ring with feedback sensors, calibrate them according to your system’s control logic to ensure precise readings and error-free control.

- Startup Testing: After installation, power up the system incrementally. Observe the cylinder as it cycles through its range, checking for abnormal noises, vibrations, or leaks. Address any abnormalities immediately.

Routine maintenance ensures consistent and optimal performance:

- Inspect seals and gaskets for signs of wear or damage during scheduled downtime.

- Keep the air supply clean and dry. Change filters and dryers as recommended.

- Monitor cylinder operation for sluggish movement or erratic stopping, which may indicate internal wear or air leaks.

- Retorque mounting bolts if the cylinder is exposed to vibration-heavy environments.

For more detailed maintenance guidelines, industry periodicals such as BBC.com often provide deep dives into equipment care strategies.

Best Practices for Maximizing Efficiency

Implementing the MSQB-30A isn’t simply an exercise in plugging and playing—effective use hinges on a holistic approach embracing design, control, and process optimization. Here’s how to unlock its full potential:

- System Simulation: Use CAD or pneumatic simulation software to virtually test cylinder placement and motion paths. Pre-visualizing complex automation layouts helps identify and resolve bottlenecks before physical installation.

- Load Calculations: Ensure that the cylinder’s rated torque and speed match your actual application needs. Oversizing leads to energy waste; undersizing results in premature wear or system stalls.

- Synchronized Controls: Integrate position feedback from the magnetic ring with your PLC (programmable logic controller) or computerized management system. Automated feedback helps adjust timing, synchronization, and fail-safe operations more rapidly than manual oversight.

- Monitoring Energy Use: Track compressed air consumption and optimize actuator sizing and sequence timing to minimize waste, boosting both throughput and operating margin.

- Training: Ensure technicians and line staff are trained in pneumatic basics—understanding how cylinders work helps diagnose issues earlier and prolong equipment life.

Troubleshooting Common Issues

No industrial component is immune to problems. Knowing what to look for—and how to address it—can minimize unexpected downtime:

- Cylinder Fails to Move: Check air supply pressure, look for kinks or blockages in supply lines, and verify that control valves and solenoids are functioning properly.

- Erratic or Jerky Movement: Often caused by inconsistent air supply pressure or contaminated lubricants. Inspect for leaks and clean air lines.

- Leaking Seals or Gaskets: Replace immediately with manufacturer-approved parts; persistent leaks indicate either excessive pressure or worn parts.

- Feedback Sensor Errors: Recalibrate sensors if the control system’s signal input does not match physical reality. Replace damaged or out-of-spec sensors as needed.

- Unusual Noise or Vibration: Investigate for loose mounting, internal wear, or air bubbles in pneumatic lines.

Emerging Trends in Rotary Pneumatic Technology

What does the future hold for rotary pneumatic cylinders like the MSQB-30A? Here are some fast-approaching trends shaping this sector:

- Smart Pneumatics: Integration of IoT-ready sensors and cloud connectivity, allowing real-time monitoring, predictive maintenance, and performance analytics from anywhere in the world.

- Eco-Friendly Materials: Growing demand for sustainable materials in manufacturing means lighter, recyclable alloys and the reduction of hazardous substances in seals and lubricants.

- Compact Multi-Function Actuators: The consolidation of multiple movements—linear, rotary, and gripping—in single, modular devices fosters even greater space-saving and system simplification.

- Energy Recovery: New designs incorporate systems to capture exhaust air energy, lowering operational costs and enhancing eco-efficiency.

- Augmented Reality (AR) for Setup: Technicians increasingly use AR glasses and software overlays to guide installation and diagnostics for complex assemblies, including rotary cylinder arrays.

Summary

In the rapidly evolving domain of industrial automation, the MSQB-30A Rotary Pneumatic Cylinder emerges as a gamechanger, marrying precision engineering with rugged reliability. Its broad adjustable range, enduring waterproof construction, and flexible integration potential make it indispensable to modern assembly, material handling, and manufacturing. By adhering to rigorous installation and maintenance regimens—and by leveraging the latest control and monitoring technologies—factory operators can drive productivity, minimize downtime, and respond dynamically to changing production needs.

The MSQB-30A is more than just another actuator; it’s a testament to engineering focused on next-generation manufacturing, where adaptability and efficiency rule.

FAQs

- What is the maximum angle of the MSQB-30A?

The maximum angle is 190°, offering an exceptionally wide range for rotary applications. - Is the MSQB-30A suitable for outdoor or wet environments?

Yes, the cylinder’s waterproof design ensures continued operation even in environments exposed to moisture or chlorine-based cleaners. - How often should I maintain the MSQB-30A?

Periodic inspections, preferably during scheduled downtime, are recommended. Check seals, lubricants, and air supply regularly as per manufacturer’s recommendations. - Can the MSQB-30A be used in high-temperature environments?

Always consult the product specifications and manufacturer’s data sheets for precise upper and lower temperature limits before deploying in extreme environments. - Does the MSQB-30A support position feedback?

Yes, it features an integrated magnetic ring that functions with compatible sensors for real-time position monitoring. Integration with your control system maximizes process reliability. - How difficult is retrofitting the MSQB-30A to an existing line?

Thanks to standard fitting and mounting dimensions, most users find retrofitting straightforward; however, be sure to check compatibility with legacy control systems.